SYNTHETIC GEMSTONES

A synthetic gemstone has the same properties

as a natural stone; that is, all the physical, chemical, and optical characteristic

are identical. The only difference is that synthetic gemstones are created

in a laboratory. So remember they are not minerals, since they are not

made by nature. If a substance is made to resemble a gemstone, but

does not share its characteristics, it is called a simulant.

Many people get confused, and unscrupulous dealers sell

simulants under the name synthetic. Simulants can be almost as difficult

to detect as synthetic gemstones, but unlike synthetics specialized detectors

can reveal differences in the physical properties and detect the simulant;

this would not generally work for a synthetic. One exeption is DeBeers'

system for detecting synthetic diamonds.

One of the simplest tools for detecting simulants is a

refractometer, which measures a property related to the speed of light

in the stone called the refractive index of the

stone. Glass is the most common simulant and will have a different

refractive index than the gem it simulates. Refractive index measurement

using a refractometer is nondestructive and can even be applied to some

stones that are mounted in small pieces of jewelry.

There are synthetic versions of many popular gemstones

and many of them have been around for a long time. Older synthetics are

simple for gemologists to detect; they were often too good (no flaws).

Some modern synthetic gemstones are more difficult to detect. It takes

experience and some suspicion. A jeweler or gemologist can usually

detect synthetics by their unusual inclusions or growth features that are

not found in a natural stones. As well, certain characteristics of some

synthetic stones, such as most early synthetic diamonds made by General

Electric (GE) behaving as semiconductors, are rare in natural stones.

Thus be skeptical of something that seems too good or unusual to run across

on an average day.

Why Make Synthetic Gems?

Some of the most important synthetic stones and simulants are mentioned

below. Mostly these are produced because they are inexpensive and replace

a natural stone. As an example, synthetic ruby is used as a gemstone, but

synthetic quartz, which does have valuable industrial applications, is

seldom used as a gemstone because natural quartz is abundant and inexpensive.

Colored varieties of quartz may be more desirable for synthesis.

Some synthetic stones are quite valuable; for example, synthetic diamonds

are selling for about 2/3 the cost of natural ones of the same quality.

Because of limitations in production and the demand of the

consumer for natural products, synthetics are never as valuable as natural

stones. One example of a limitation is that very large synthetic diamonds

have not yet been grown in gem quality and thus do not yet compete for

this market. But even this will change soon!

Yet synthetic gems continue to be made. One reason

for this is that color matching of natural gems may be expensive and time

consuming, while synthetic gems may be very easily matched. Another

reason is that some jewelry requires near flawless stones and this is a

cheaper way to get them. No simulant quite matches the color of an

emerald, but a synthetic may. Synthetic emeralds sell for about a

third the price of a natural stone. As well, some natural stones

are so rare that it would be impossible to get a great stone, for instance

natural alexandrite, yet a synthetic is easily obtained at a fraction of

the cost. Color, clarity, and rarity with economy, that is the ultimate

answer.

Commonly synthesized gemstones include: alexandrite, corundum,

diamond, emerald, opal, spinel, and the colored varieties of quartz.

Several can be made by the same process. The major synthetic products

and processes are discussed below.

Synthetic Corundum (and gems created by similar

methodology)

Flame fusion--this method perfected by August Victor

Lewis Verneuil (a French chemist who lived from 1856-1913) and is often called

the Verneuil method. Use of flame fusion predates the publication

of Verneuil's work in 1902. The first synthetic corundum sold as

ruby was referred to as "Geneva Ruby." It appeared on the market around

1885 and was sold as natural material at first. Gemologists soon

doubted Geneva rubies had a natural origin and Verneuil began making a

similar but superior product around 1888 using powdered aluminum oxide

(Al2O3)

to grow an elongate, rounded mass of corundum, somewhat carrot shaped, called a boule. Powdered

Al2O3

and

a coloring agent such as chromium are fused (melted) as they are dropped

through the flame of a hydrogen and oxygen torch. The apparatus used is similar

to a blow torch. Verneuil never patented his technique and many companies

have produced corundum using his method almost without modification

from what was done in 1888!

The corundum is grown on a seed or rod of synthetic corundum.

Boules up to several hundred carats (about an inch wide by 3 inches long)

are produced. Synthetic corundum gem material can have some properties

not seen in natural stones which allow for moderately easy detection.

One such property is curved growth lines that are visible with 10 times

magnification another is the presence of gas bubbles.

One reason that this method was very popular is that watch

bearings are made of corundum; the Swiss no longer needed to import corundum

for their bearings, but could grow it and fashion it in their factories

to make their famous jewel-bearing watches.

Though many companies used this to create gems, perhaps

the most important advances in this method were achieved by the Linde (pronounded

lindy) Air Company, Chicago. They invented methods to control the

growth direction of the boule's crystallography and also invented the synthetic

star sapphire in 1947. Other material made by this method includes:

rutile, spinel, and strontium titanate. Rutile and strontium titanate were

important as diamond simulants until cubic zirconium took over.

Crystal pulling (Czochralski process)--This method

is used extensively in the production of ruby, alexandrite, YAG, and other materials for lasers;

it is also used for gems including: corundum, alexanderite, and the diamond

simulants GGG (Gadolinium Gallium Garnet) and YAG (Yttrium Aluminum Garnet),

which have no natural counterparts.

A very important use is in the high-tech field where single

crystal boules (carrot-shaped rods) of materials used to make semiconductors

and other types of electronic wafers, such as those used for computer chips, are pulled using this method.

After a large boule is pulled (diameters up to about 10 inches or 24.5

cm), it is sliced to make the thin wafers.

To do the pulling, a melt (hot liquid) of the correct

composition is prepared in a heat resistant crucible that is usually heated using radio

frequency methods and a seed crystal is lowered into it. The temperature

is reduced to just above the melting point of the seed, and the seed is

then rotated and slowly lifted out of the melt. A boule-like rod

is created as the seed is pulled out. The method creates large, very

pure crystals. One unusual aspect of the Czochralski method is that

hollow tubes and other shapes can be manufactured using this method.

Hydrothermal method--this method uses a high temperature

and pressure vessel that acts like a pressure cooker. Al2O3

for corundum, SiO2

for quartz, or a combination of the ingredients needed for emeralds, are

dissolved in a hotter part of the vessel's chamber and reprecipitate/crystallize

on seed crystals in a cooler part of the chamber. Crystals are formed

rather than a boule and the material appears more natural. A platinum

or silver wire sticking through the crystal gives it away, but when the

synthetic material is cut away from the wire and the seed crystal, these

gems may be difficult to detect.

A lack of natural inclusions and perhaps flakes of metal

from the walls of the growth chamber of the vessel may indicate a synthetic

gem. Gems grown by this method include: emerald and other varieties

of beryl (for example that made by Linde Air Company and Tairus Ltd.),

quartz (made by many companies for its use in electronics and a few for

jewelry), corundum, and alexandrite.

Unlike the flame fusion and Czochralski methods, the hydrothermal

(and flux growth mentioned below) allow the growth of chemically complex

minerals that can not be formed by flame fusion or melting in Czochralski

methods. This is because the ingredients (constituents) are either

too volatile or not compatible at normal pressure and the high temperatures

needed for melting. However, if the constituents are dissolved in

a fluid in a high temperature/hotter part of the hydrothermal apparatus,

the fluid can then migrate and can cool and precipitate in a cooler region

of the same device. Thus dissolution of ingrediants and precipitation

of gems occur because of a temperature gradient. Temperature gradients

exist in the earth, and hydrothermal (hot water) veins often contain interesting

mineralization such as gold, silver, emeralds, etc. that were dissolved

in the fluid deeper in the Earth's interior where it is hotter and reprecipitated

as the hot water rises through the Earth's crust and cools.

Flux growth--This method is popular for ruby, emerald,

alexandrite, and other exotic substances such as GGG, a type of garnet.

Crystals are grown in a crucible (vessel or pot) that contains feed of

the same composition as the mineral to be grown plus flux. Flux is

a substance used to lower the melting point of the feed so that crystals

can be grown at temperatures below the normal melting point of the gem

material. Flux is also a name used for applications in welding and

soldering, but the meaning of the word is not quite the same as in gem

making. The crucible is often made of platimum that has a very high

melting point. Sometimes seeds of the substance that is being grown

are suspended in the melt, as in the Gilson method of creating emeralds.

Some gems, such as Ramaura Ruby (trade mark), are created by self-nucleation.

That is, no seed is added.

The flux dissolves the constituents and as the vessel

containing the flux is cooled, the mineral/gem of interest crystallizes.

If allowed to cool completely, the gems would be encased in the flux.

So the flux is either poured off or drained before it solidifies.

Not only is it important not to cool below the flux's freezing point, but

it is also important to cool very slowly to grow as large a crystal(s)

of the gem as possible.

Synthetic Diamond

High pressure and high temperature method (HPHT)--This

method is the classic method first used by GE in 1954 to create industrial

diamonds and led to the creation of gem grade diamonds by around 1970.

Russian scientists (Kiev Synthetic Diamond Research Institute, 1967) made

the first synthetic gem diamonds. Several gem diamonds have been

produced by companies including DeBeers and General Electric; however,

they were not an economic success. On the other hand, industrial

diamonds used in drill bits and saws have been profitably produced by these

methods for the last several decades.

These diamonds are grown under similar conditions to natural

stones, temperatures of around 1,500-3,000oC and pressure of

between 852,365 to1,500,000 pounds per square inch (58,000-100,000 atmospheres).

A metal is mixed with the carbon used to grow the diamond and acts as a

flux. The metal may be iron, nickel, etc. Some diamonds created

by this method have metallic inclusions and can be attracted by a strong

magnet.

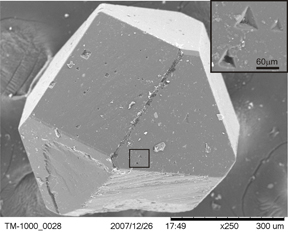

HPHT diamond displaying both cubic and octohedral forms in the

crystal. This diamond has

well developed crystal faces, but there are several etch(?) pits such

as those on the octohedral face,

which are magnified in the upper right corner of the photo. The

etch pits on the octohedral face

are triangular (octohedrons are made of 8 triangular faces. Those

on the cubic face are cubic. This

suggests a common method of formation.

Chemical vapor deposition method (CVD)--This method

is often used for depositing a thin layer of diamond on cutting tools or

other objects that need a hard surface. The term vapor implies a

gaseous phase and the gas used is often methane (CH4).

There is no need for high pressure, but temperatures are moderately high,

between 750-1,000oC.

Not all substances can be coated; it depends on their resistance to melting

and whether they form a carbide coating (good) or absorb the carbon (bad).

Most importantly, it is possible to grow a diamond on an existing diamond

substrate, and the rates of growth may be quite high. A gem quality

3-carat diamond may be grown in a few days. Because a single-crystal

seed diamond can be used to orient the growth, the diamond produced may

be grown with a controlled direction that allows for best cutting properties.

Opal

Opal is a hydrous (water-containing) form of silicon dioxide.

Opal's synthesis is achieved by creating uniformly sized, microscopic spheres

of silicon dioxide that are packed closely together, forming a solid mass.

The microscopic spheres act like a diffraction grating, breaking up light

into many colors. The exact methods used are proprietary and difficult

to achieve. However, it is clear that spheres of silicon dioxide

are created in an aqueous solution and settle slowly to the bottom of a

vessel. Once a mass of these spheres is created, heating or other

methods are used to consolidate the spheres into a mass.

Both white and black opal are made. The most prominent

company making synthetic opal is Gilson Opal (after Pierre Gilson's product

that first appeared on the market in 1974).

SIMULANTS

Substances, either real minerals or totally manmade,

can be called simulants if they are used to simulate another type of gemstone.

The most important gemstone simulated by many different materials is diamond.

Diamond simulants must have good fire like a true diamond, but many simulants

are overly fiery. Other simulants may be used for ruby, emerald,

sapphire, etc.

The most common simulant is glass. Colored glass

and glass with special characteristics can be used to simulate most gemstones.

For example, fiberlite (a fiber optics glass) is used to create simulants

of cat's eye (a stone showing chatoyancy), and Slocum stone a glass with

reflective foil simulates opal.

Cubic Zirconium (CZ)

At present, CZ is the most successful simulant for diamond.

However, moissanite (silicon carbide) is catching up.

Skull melting method--this method was invented

to produce cubic zirconium (CZ) from zirconium oxide powder.

Zirconium has such a high melting point (2,730oC)

that when melted, it cannot be contained in a crucible or other simple

containment vessel. The answer, simplicity itself, is to heat the

zirconium powder from the inside and use the remaining zirconium powder

surrounding the hot part as a containment vessel, with the tightly packed

unmelted powder acting as the containment walls. This is accomplished

by wrapping a radio frequency generator around the mass of powder.

The inside of the mass is heated and melts. Upon cooling the interior

portion is clear and inclusion-free. CZ is perhaps the best of the

diamond simulants. Because it is made by a simple method, it is relatively

inexpensive.

Moissanite (SiC)

Moissanite is named after the French chemist Ferdinand Henri

Moissan, a Nobel Laureate, who discovered natural silicon carbide (SiC)

in meteoric material at the Canyon Diablo Meterorite Crater in Arizona.

He won his Nobel for the isolation of the element fluorine in 1906.

He tried to make synthetic diamonds, but apparently failed though he did

grow silicon carbide.

Silicon carbide is also called carborundum and is used

as an abrasive. Carborundum is made by heating sand and coal to react

the coal's carbon with silicon in the sand. This process does not

produce gem quality material, though occassionally larger crystals may

be faceted. It has a hardness of 9.25 on Mohs' scale and has greater fire

than that of diamond.

Gem quality moissanite is made by a sublimation processes.

That is the constituents are vaporized and recrystallize by going directly

from a gas to a solid. This is done in a graphite crucible at a temperature

of around 2,500oC and the gases crystallize on a seed of SiC

to make a boule.

The production of colorless (perhaps with slight green

accents) SiC was a great techological achievement. Because moissanite

is not found in this form in nature, it is called a simulant here.

Because it is difficult to make, moissanite is expensive, though considerably

cheaper than diamond, which it simulates. The future for SiC in the

gem industry is uncertain. It may surpass cubic zirconium, but it

is unclear at this moment what will happen.

Return to the Biological Sciences and Geology

Website